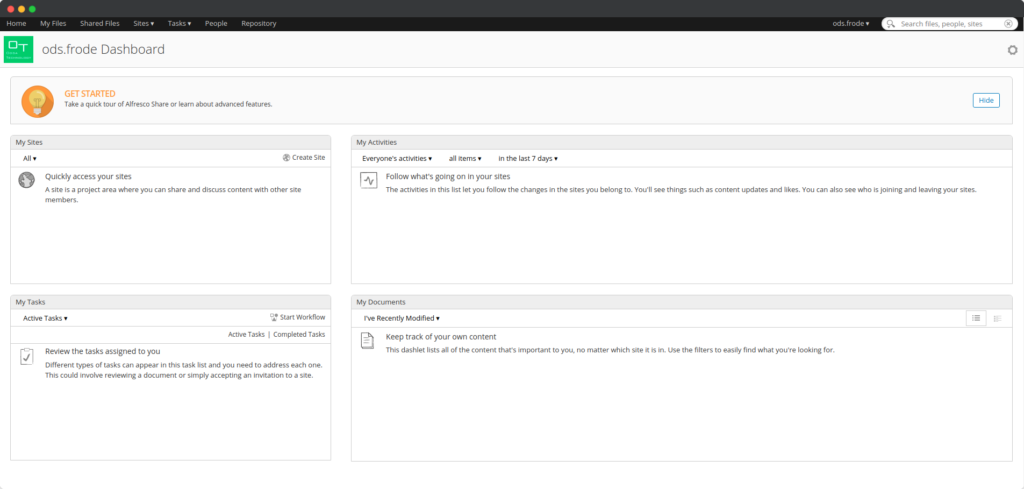

Data Visualisation

Fast data visualisation and input in easy to use systems

Full item tracking

Correlating data from many types of sources

Cost savings in quality control process

Data organised in APIs

Easy Access to Data within the system and other tools, like PowerBI